Systems Integration

Brican is, above all else, a systems integrator. We have a deep knowledge of not only the individual components of the modern and manufacturing process – but how to make these disparate systems work efficiently together. And we do mean everything – ranging from the simplest and safest conveyor through to the most complex mechanical/optical inspection system. We pride ourselves on the Brican ability to provide a seamless solution – where every piece of the complex puzzle is a perfect fit.

CNC AUTOMATION

We know – intimately – every single step of the CNC process. Brican can take the highest-end CNC machine and custom-configure it to the most demanding and complex specifications. All of the coding, hard-wiring and customization is done – followed by rigorous testing. Only when we are satisfied that the machine(s) are fully and turnkey optimized will they leave our shop and enter yours.

CONTROL

Brican know-how provides the brains behind systems integration, with control systems completing the central nervous system. Whether it’s Programmable Logic Controllers (PLC), Human-Machine Interface (HMI) – or everything else that goes with it – Brican has the expertise. We know how to exert control – effortlessly.

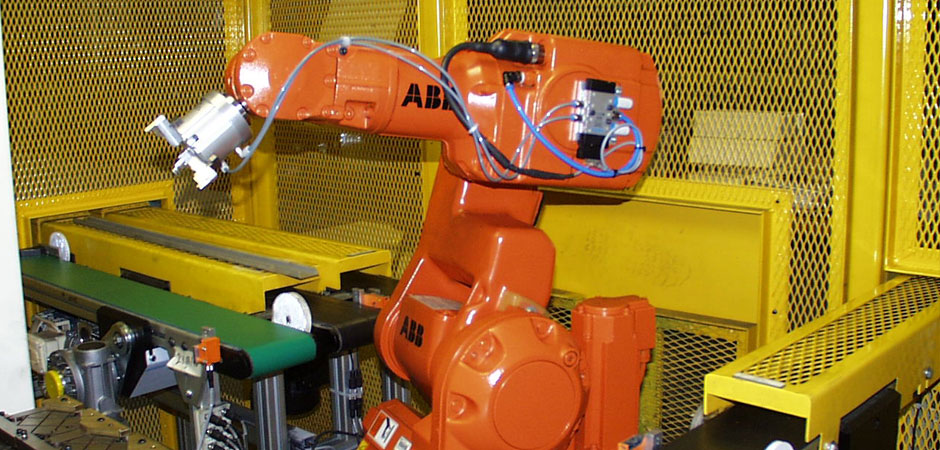

ROBOTICS

It’s not news that robotics has utterly transformed the manufacturing sector. But it may be news to you that Brican has the know-how to utterly transform robots. Through sophisticated programming and ingenious end effectors, we can maximize your productivity with a minimum of hassle. And, like everything else, we take pride in our expertise at system integration. We can envision, and implement, a single and seamless workflow.

PICK AND PLACE

At Brican, we take the strain out of repetitive. We can customize a solution capable of far more than simply picking or placing materials. With the right gripper or end effector, there’s a long list of what a robotic arm can do, including: Sort, stack, align, move, adjust, order, load, unload, pack, etc. Robots can also work (tirelessly) with materials so small, heavy or difficult to handle that they pose a challenge for a human being. Many customers utilizing Brican solutions have quickly regained their investment through increased efficiencies and reduced labour cost.

CNC LOAD/UNLOAD

We are specialists in the precision and detail-oriented work required for smooth load/unload processes. We fabricate custom tool-holding work on-site, then build a solution for seamless material transfer – whether it’s a single CNC machine or multiples in an assembly line. Our solutions include robotics, conveyors, safety guard fences – everything to ensure you are both fully automated and compliant with existing safety regulations. And – as with everything else we do – we are meticulous.

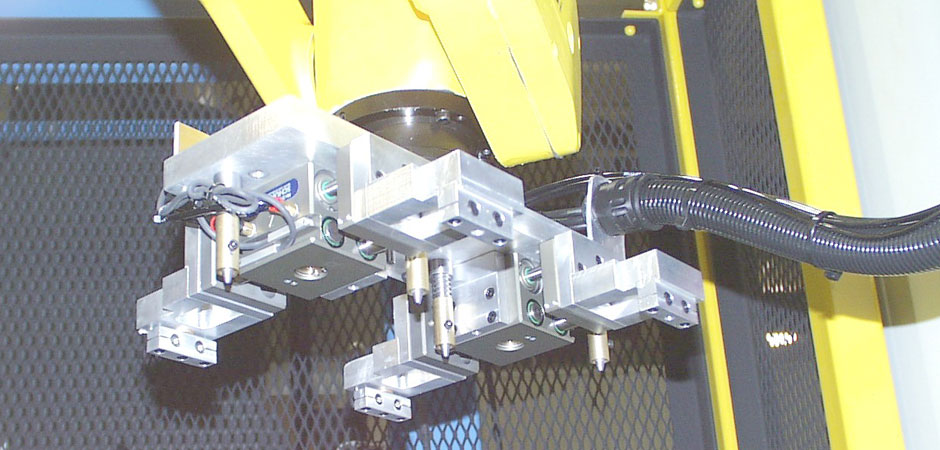

END EFFECTORS

As part of a Brican solution, we can design end effectors to handle pretty much any task – or part. We are experienced with impactive, ingressive, astrictive – and even contigutive requirements, and can custom-design a solution for your workflow and materials. (And of course, we have the skills and expertise to customize a solution that combines any combination of the above). We’ll help you select the best robot for the task, then take care of the end effector design, fabrication, programming and testing. We’ll even build a fail-safe guard to ensure that workers are always in a safe zone. The end result is a robot that never drops the ball.

PART TRANSFER

When it comes to moving something from point “A” to point “B” – there’s nothing better than an “R” – Robot. With precision programming (and even multiple end effectors), robots can move objects with greater accuracy and virtually zero downtime. A single robotic arm, properly equipped, can even move multiple different materials from one spot to another. A Brican specialist would be happy to assess your workflow for robotic integration. And he (or she) will do so with a very human touch.

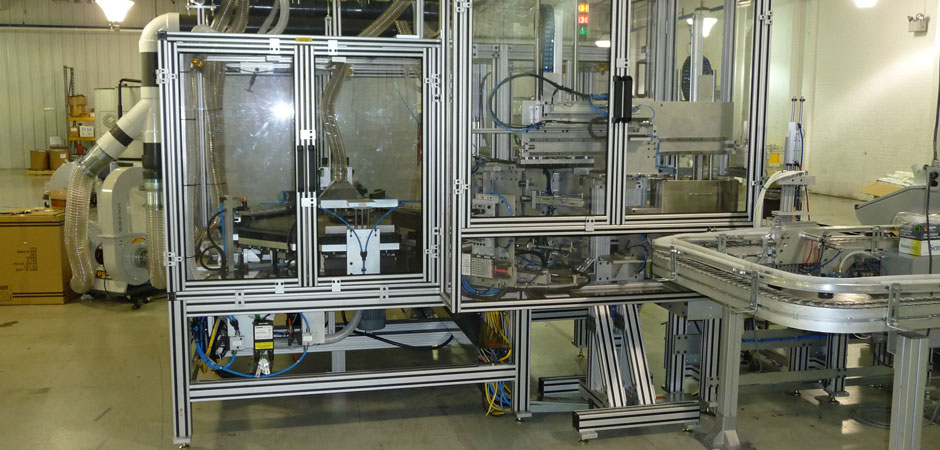

SPECIAL PURPOSE MACHINES

One of our specialities at Brican – a specialty upon which we’ve built our reputation – is of the design and manufacture of Special-Purpose-Machines. These are “one-off” creations designed to suit a client’s unique needs/applications, where no off-the-shelf solution exists. We apply every creative and technological tool at our disposal in the design and manufacture of these machines – and won’t rest until we’re satisfied we’ve provided the most reliable, safe, and advanced value-driven solution possible. Frequently, our creations have resulted in clients obtaining a substantive competitive advantage in their sectors – and significantly greater output/profit margins.